|

Home | Search | Browse | About IPO | Staff | Links |

|

Home | Search | Browse | About IPO | Staff | Links |

|

Granite City Offers Valuable Lesson On The Sewers. No other aspect of America's infrastructure is so ignored or misunderstood. Out of sight, out of mind, as the old saying goes, and it certainly applies to sewer systems. As long as the dirty water goes away, who cares about the condition of the pipes? The fact is, sewers play a crucial role in determining the quality of life enjoyed by a community. Their importance goes far beyond just carrying wastewater to the local treatment plant. Sewers are an important infrastructure element that can help lure (or discourage) industrial growth. Sewers and sewage treatment also are vital to public health and environmental protection. Furthermore, if local sewers aren't maintained properly, or if they are damaged in some way, the repair costs and resulting inconvenience can wreck a city financially and cause taxes and user fees to skyrocket. The story of the Nameoki Sewer System in Granite City, Illinois, (population 32,769) serves as an excellent example of how important sewers can be. Sewer problems crippled the town economically for years, and only recently did the city discover a workable solution to its massive sewer problems. Granite City, a heavily industrialized town located just across the river from St. Louis, can't be faulted for a lack of foresight. In the early 1950s the city built a sewer system in a part of town called the Nameoki district, which now comprises about one-third of the city. The system was, for that era, state-of-the-art, with 8, 10, 12 and 15-inch vitrified clay pipes. To avoid building expensive pumping stations, city officials elected to install the pipes deep in the sandy soil, anywhere from 10 to 20 feet, with enough grade for a functional gravity-flow system. The sewer was efficient and cost-effective, and it served Granite City well for nearly a decade. However, in the late 50s and early 60s there were several developments which affected the quality of the Nameoki sewers. When the sewers were installed, the water table under Granite City was abnormally low, probably due to low rainfall amounts which lowered the Mississippi River level. It was also about this time that the Corps of Engineers built the Chain of Rocks Canal parallel to the Mississippi River. The addition of the canal further raised the ground water table and submerged many of the sewer pipes. Within a few years after the Nameoki project, the water table was near the level of the sewer pipes. In the early 70s Congress enacted the Clean Water Act, which, among other things, put restrictions on industrial water use and discharge. As a result, several industries located in Granite City quit pumping water from below ground, causing the water table to rise again. This was the final straw that doomed the Nameoki sewers. The sandy soil around the sewers became saturated. Some of the water infiltrated into the sewer lines through small leaks at the joints, carrying soil that clogged pipes and congested treatment facilities. Even worse, the eroding soil left voids around the pipes causing them to shift and sag. Some of the clay pipes cracked, others collapsed. There were numerous potholes and cave-ins. The cost of the damage was, by Granite City standards, astronomical. Reserve funds were quickly depleted and soon the city was in a serious financial dilemma. "Between 1970 and 1985, we were spending an average of $600,000 a year on sewer repairs," said K.P. MacTaggert, City Comptroller. In addition, property values declined and capital improvements were postponed. In other words. Granite City's economy literally went into the sewer. "Our city had a $10 or $11 million budget at that time. The sewer repairs just devastated us," admitted Mayor Von Dee Cruse, who has been in city government for 40 years. "Sometimes a single point repair would cost $50,000, and then we would have to turn around and repair the same spot a few months later. It was a major problem for our city, and solving it was my top priority when I was first elected mayor eight years ago." Granite City's sewer collapses placed a tremendous financial burden on the city. Improvements like new streets and public works projects were put off indefinitely. Sewer-related complaints poured into city hall daily. Meanwhile, the situation grew steadily worse. Desperate for answers, in 1985 the city hired Horner & Shifren, Inc., Design Engineers/Architects, to study the problem. The firm responded with four possible solutions: reconstruct the sewers in place; replace the sewers so all pipes are above the water table; institute a continuous program to chemically grout the sewers to fix the leaks; or use the Insituform trenchless pipe rehabilitation technology to rebuild the lines without digging Already strapped for funds, the city couldn't afford to dig up and replace the sewers. Excavating the lines would take years and create enormous traffic congestion. Grouting was seen as an on-going maintenance process, not a long-term solution. The only acceptable alternative was the Insituform process. "We were a little skeptical about Insituform at first," admitted Mayor Cruse. "We looked into it very carefully before we decided to use them." The city's first experience with Insituform's patented technology was in 1986 when Granite City hired the company to repair two crumbling sewers. That successful introduction to Insituform was followed by other equally successful Insituform jobs. Finally convinced, in 1989 Granite City decided to follow the engineering firm's recommendation and rebuild all the troubled Nameoki lines with the Insituform process. Using a revolving loan obtained through the Illinois Environmental Protection Agency, Granite City financed a $3.7 million reconstruction effort to rebuild continued in page 7..... April 1993 / Illinois Municipal Review / Page 5 How Insituform* Is Installed Insituform is a proven process for reconstructing damaged pipeline systems in municipal and industrial applications without digging. A flexible, resin absorbent, fabric Insitutube*, coated on the outside with an elastomeric material, is custom engineered and manufactured to fit the cross-section, length and required design thickness for the damaged pipe. The Insitutube is saturated (wet-out) with a liquid thermosetting resin. Resin selection is determined by the effluent characteristics and type of service (gravity vs. pressure). Insituform is installed using an inversion technique which allows the material to negotiate bends, accommodate changes in pipe alignment and size, and span missing pipe segments. A new Cured-in-Place Pipe (CIPP), or Insitupipe*, is formed inside of the existing conduit as follows (other inversion techniques can be used for several applications):

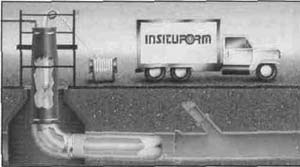

STAGE 1 The resin saturated material is installed in the existing pipe through a manhole or other access point via an inversion standpipe and inversion elbow. The Insitutube is cuffed back and banded to the inversion elbow, creating a closed system that allows the water inversion process to take place.

STAGE 2 Water from nearby hydrants, or other convenient source, is used to fill the inversion standpipe. The force of the column of water turns the wet-out Insitutube inside-out and into the pipe being reconstructed. As the Insitutube travels through the pipe, water is continually added to maintain a constant pressure. The water pressure keeps the Insitutube pressed tightly against the walls of the old pipe.

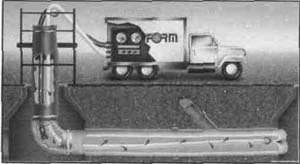

STAGE 3 After the Insitutube reaches the termination point, the water in the line is circulated through a heat exchanger where it is heated and returned to the Insitutube. The hot water cures the thermosetting resin, causing it to harden into a structurally sound, jointless "pipe-within-a-pipe," an Insitupipe*.

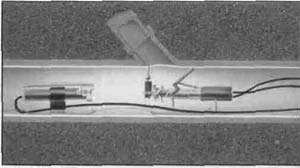

STAGE 4 Once the Insitupipe has hardened and cooled, the water pressure is released and the ends are trimmed. Service connections are reinstated internally with a remote control cutting device or by man-entry techniques. The Insituform operation is then completed, and the newly installed pipe is ready for immediate use. All this is accomplished without excavation. Page 6 / Illinois Municipal Review / April 1993 continued from page 5...... 50,000 feet of damaged sewer pipe. Insituform Missouri, a division of Insituform Mid-America, Inc., was awarded the project. The work began in 1990 and was completed in 1992. The result? Sewer repair expenses in the Nameoki district have dropped from an average of $600,000 annually to nearly zero. "Solving the Nameoki sewer problem helped us avoid a financial crisis," explained Mayor Cruse. "As everybody knows, fixed expenses like electricity, labor costs, insurance and so forth have gone up a great deal over the past 20 years, so our city budget is a lot bigger than it used to be. Had we not solved our sewer problems, we would either have had to eliminate vital city services or raise taxes substantially to meet our expenses. The money we're saving on sewer repair now goes to police and fire protection, street repair, and so forth. Fixing our sewers has been a real blessing for our city."

The Insituform process rebuilds sewers without digging. A custom-made felt tube is saturated with thermosetting resin and inverted into the damaged line by water pressure. The water within the line is then circulated through a boiler above ground and returned to the line. The hot water cures the resin, turning the tube into a strong, structural, jointless pipe-within-a-pipe. The new Insituform pipes eliminate infiltration and exfiltration, so soil stays out of the sewers. Also, the new pipes are strong yet flexible, so they can withstand soil shifts without cracking.

Left to right: Brett Hanke and Gary Penrod According to Public Works Director Brett Hanke, using the Insituform technology saved the city money in more ways than one. "Politically it was great," said Hanke. "There were no disruptions to local traffic or property, so we had almost no complaints while the work was in progress. The Insituform people also performed 19 point repairs for us prior to installing the Insituform pipes, and they

did them at a cost that was much lower than we had been paying. As I recall, they did all 19 point repairs for about $60,000, which is what we had been paying for a single repair. They worked in some adverse conditions and did a very professional job. I was impressed." MacTaggert, the City Comptroller, views the situation from a money management standpoint. "Instead of spending huge amounts of money on a problem with no foreseeable solution, we made an investment in our infrastructure and solved the problem. We were spending over a half million dollars annually on the Nameoki sewers. Now we'll spend around $260,000 annually to retire the debt for fixing them. We spent money to save money, so it was a good investment."

Mayor Von Dee Cruse "I view the Nameoki project as one of the major accomplishments of my administration," said Mayor Cruse, who will retire from public service in May. "It has significant long-range ramifications for the economic stability of this city. I'm extremely proud that we were able to solve the problem for the people of Granite City." How important are good sewers? Perhaps it is no coincidence that the American Steel Company is about to reopen a plant in Granite City that had been closed for some time. The facility will employ 1200-1500 workers. April 1993 / Illinois Municipal Review / Page 7 |

|

|