|

Home | Search | Browse | About IPO | Staff | Links |

|

Home | Search | Browse | About IPO | Staff | Links |

|

Today's

Save 50 percent with concrete and foam walls

Q: Jim: I plan to build a new house or

add a large room over a basement. I

want super-insulated walls and extra

strength to resist tornadoes and hurricanes.

What is the best construction method for

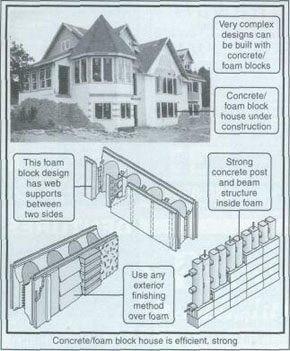

me? A: Dear Paul: Concrete/foam block house construction is one of the best new house construction methods available and it would be an excellent fit with your needs. It produces super-efficient airtight walls with insulation values up to R-32 and can resist tornado and hurricane force winds up to 150 mph.

A finished concrete/foam block typically looks no different than any other house on your street. The simplicity of this construction method, along with its super strength, gives your architect or builder even more design flexibility. This same construction method can be used for the foundation, making your basement as comfortable as your living room.

As compared to a similar-sized stick-built house constructed with 2x4 walls, a concrete/foam block house has much lower utility bills, up to a 50 percent savings. These tremendous monthly savings can easily pay back any higher initial construction costs quickly. Since the construction methods are so simple, you can help with some of the basic set up and reduce the construction labor costs.

These utility bill savings result from more than just the higher wall insulation levels. By their basic design concept, with interlocking tongue-and-groove blocks, concrete/foam block houses are very airtight. With the super-strong concrete inner-structure, these houses settle very little so they remain airtight literally for as long as they stand.

A secondary benefit of the heavy concrete and the air tightness is the noticeably reduced outdoor noise transmission through the walls. The heavy mass is most effective at blocking the deeper, low frequency type of rumbling sounds. Since these houses are so efficient, they require smaller, less expensive furnaces, air conditioners or heat pumps to be installed.

With the heavy concrete structure inside the walls, the energy savings and efficiency can be even greater in the summer. The tons of concrete act as thermal mass to moderate temperature swings indoors throughout the day and night. This naturally maintains more even indoor room temperatures and minimizes some of the peak electricity demand on hot afternoons.

The simplest, and oldest type of concrete/foam block construction is the "Legos" method. Basically, the wall is constructed of large hollow lightweight (5 to 10 lbs.) expanded polystyrene foam blocks, similar to common foam coolers. You just stack up the interlocking foam blocks to make the wall. This is the part of construction that you can help with.

Once the walls are completely stacked, openings for windows and doors are easily cut into the foam and the openings are framed. Next, reinforcing steel rods are slipped inside the hollow block cavities. A concrete truck, with a pump attachment, pumps the concrete into the openings at the top of the wall. The concrete flows throughout the wall cavities.

To reduce transportation costs of the large hollow blocks to your building site, many manufacturers are now offering half blocks or special flat insulating foam panels. These blocks or panels are assembled into full blocks at your building site when the house is assembled. Check

James Dulley is a mechanical engineer who

writes on a wide variety of energy and utility topics. His column appears in a large

number of daily newspapers.

18 ILLINOIS COUNTRY LIVING JANUARY 2001  with your local professional builders association for builders familiar

with these methods.

with your local professional builders association for builders familiar

with these methods.

These half blocks are assembled in various manners. Some true half blocks have interlocking teeth on the inside of the mating blocks that slide together. Others use a plastic or a metal web to position and attach the two halves or flat foam pieces together. This web method provides a convenient attachment point for the interior and exterior wall finishing materials.

The exterior of a concrete/foam block house can be finished with any traditional finishing material - brick, siding, stone, stucco, etc. When using the half block design, the exposed end surfaces of the connecting webs provide a strong attachment point for interior drywall and exterior materials. There are several newer earth-friendly box designs that use either recycled insulating foam or wood materials mixed with cement to make the insulating blocks. These blocks are stronger and heavier than virgin foam blocks, but still easy to handle. These walls are assembled and filled with reinforced concrete by the same method as all foam blocks.

For more information, write for (instantly download - www.dulley.com) Utility Bills Update No. 507 - list of 18 manufacturers of concrete/foam blocks showing sizes, R-values, block weight, descriptions, prices and construction details. Please include $3.00 and a business-size SASE. James Dulley, Illinois Country Living, P.O. Box 54987, Cincinnati, OH 45254. JANUARY 2001 ILLINOIS COUNTRY LIVING 19 |

|

|